Mimtec specialise in this process and can advise you on what can be achieved with careful component and tool design.

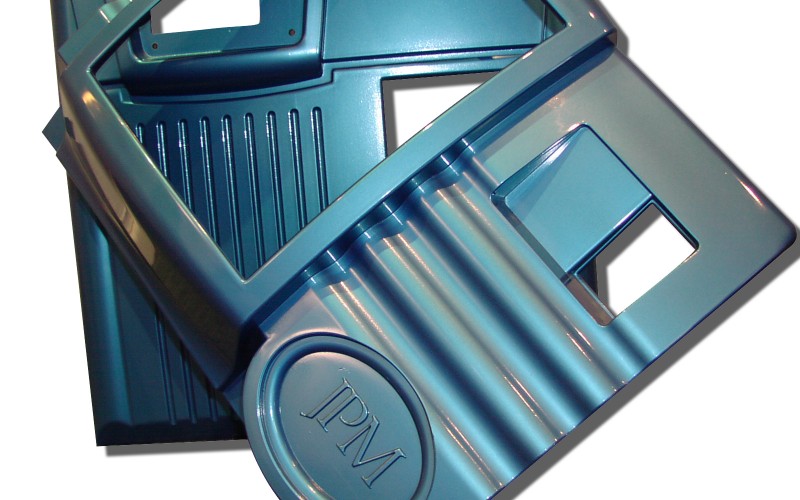

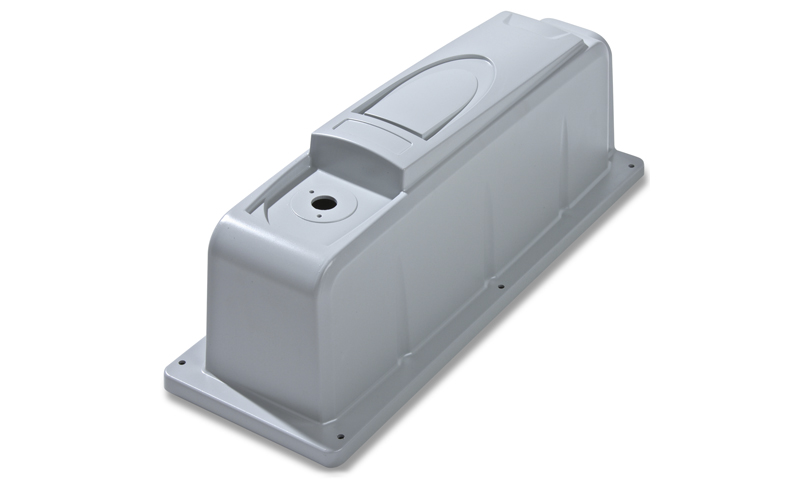

Pressure forming uses compressed air to force the sheet into contact with the tool facing. This enables textures, undercuts and fine detail to be formed into the face of the part. Using this technique detail similar to injection moulding can be achieved on the toolface side of the component.

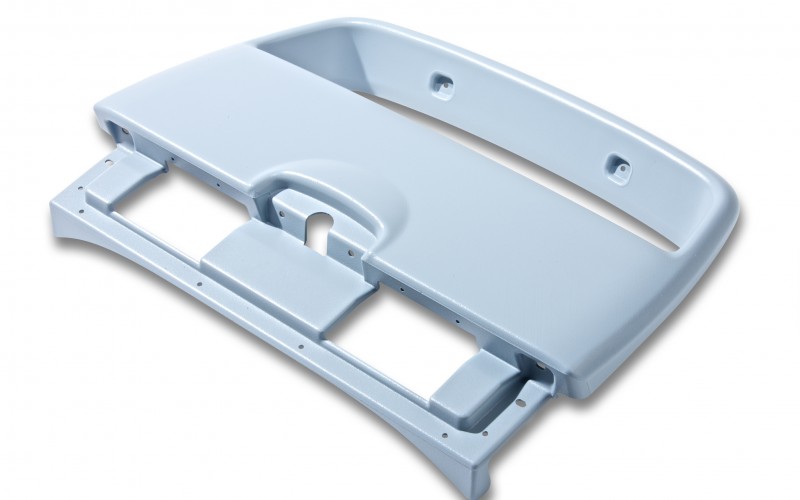

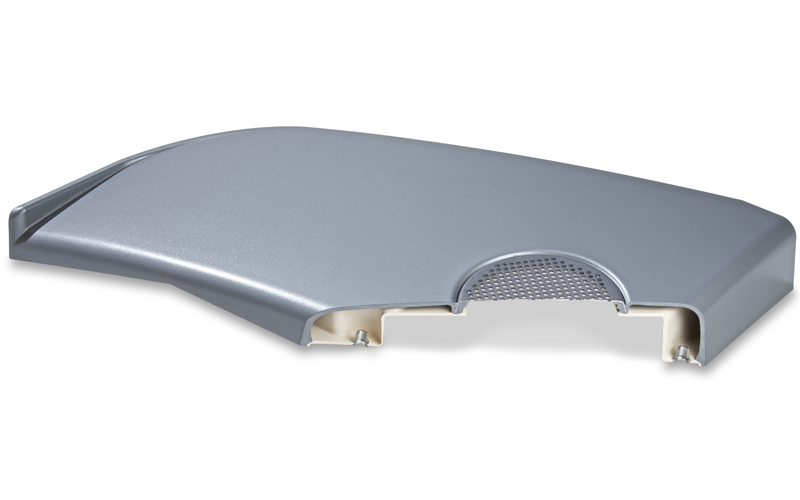

Twin sheet forming is used to pressure form a part from 2 sheets of material in a single operation, this results in a hollow component that can be very strong but light.